Water is the source of life, and the origin of mankind comes from water. More than 90% of the human body is composed of water. The continuous renewal of cells and the metabolism of life are inseparable from the nourishment of water. Due to natural and human factors, the raw water contains various impurities and cannot be directly consumed by the human body or participate in industrial production. The significance of the existence of urban water plants is to remove these components that may harm the human body or industrial production, so that the purified water can meet industrial production and human needs.

Now let Ruilang take you to understand how tap water is produced.

Production process of tap water

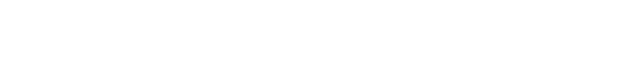

1. First, the first-stage pumping station pumps water from rivers and lakes to water plants (different areas have different water intakes, and the water source directly affects the quality of drinking water in a region);

2. After coagulation, precipitation, filtration, and disinfection, the water is fed into the tap water pipeline at high pressure from the secondary pumping station. Generally, the main pipeline uses prestressed concrete pipes, steel pipes, PE pipes, ductile iron pipes and other pipe materials;

3. The water is finally diverted to the user tap. The whole process has to go through multiple water quality tests, and in some places it needs to go through a second pressurization and a second disinfection before it can enter the user’s home.

Conventional water treatment processes in water plants are coagulation, sedimentation, filtration and disinfection. Let’s take a look at these four different processes in turn.

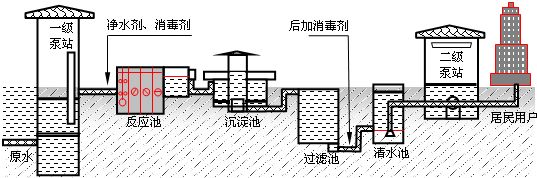

01 Conventional treatment-coagulation

After the raw water is lifted by the water intake pump room, it is first treated by coagulation process, namely: raw water + water treatment agent → mixing → reaction → alum flower water From the uniform mixing of the agent and water until the formation of large-particle flocs, the whole process is called coagulation. .

Commonly used water treatment agents include polyaluminum chloride, aluminum sulfate, and ferric chloride.

The mixing process is required to be completed quickly after adding the medicine. The purpose of mixing is to disperse the medicine quickly and evenly in the water through vigorous hydraulic and mechanical stirring. The water treated by the coagulation reaction flows into the sedimentation tank through the pipe and enters the second stage of water purification.

02 Conventional treatment-precipitation

The process in which the flocs formed in the flocculation stage are separated from the water by gravity is called flocculation sedimentation, which is carried out in the flocculation sedimentation tank. After the water flows into the precipitation zone, it is distributed along the entire cross-section of the water zone, enters the precipitation zone, and then flows slowly to the outlet zone. The particles in the water sink to the bottom of the pool. The flocculated sludge is continuously accumulated and concentrated, and discharged out of the tank regularly.

自来水厂沉淀工艺

03 Routine treatment-filtration

Filtration generally refers to a process in which a granular filter material layer with voids such as quartz sand traps suspended particles in water through adhesion, thereby further removing fine suspended impurities, organic matter, bacteria, viruses, etc. in the water, and clarifying the water.

Since the trapped dirt will stay on the filter layer, if the filter layer is not cleaned for a long time, the trapped microorganisms will multiply, and the dirt will accumulate more and more, which will cause secondary pollution of the filter layer and affect the quality of the effluent. The filter layer should be backwashed regularly with better washing effect.

In the conclusion of the book “High-quality Water in Buildings-Safe and Tasty Drinking Water” by Kenji Yamada (Japan), it is particularly emphasized that “in order to solve the problem of microorganisms generated by activated carbon and other adsorption devices and membrane treatment and vice versa , A recoil device should be set up for regular recoil.”

04 Routine treatment-disinfection

1. Chlorine disinfection

After the water is filtered, the turbidity is further reduced, and at the same time, residual bacteria, viruses, etc. lose the protection or attachment of turbidity, creating good conditions for disinfection after filtration. Disinfection does not eliminate all microorganisms, it only requires the elimination of pathogenic microorganisms.

Although the water can be coagulated, precipitated and filtered to remove most bacteria and viruses, disinfection can ensure that drinking water reaches the bacteriological indicators of drinking water. At the same time, it keeps a certain amount of residual chlorine at the end of urban water pipes to control bacterial growth And prevent pollution.

The amount of chlorination (liquid chlorine) for disinfection is between 1.0-2.5g/m3. The hypochlorous acid, which is mainly generated by the reaction of chlorine and water, oxidizes inside the bacteria, destroys the bacterial enzyme system and causes the bacteria to die. The disinfected water is raised to a certain water pressure from the clean water pool through the water pumping station, and is sent to thousands of households through the water transmission and distribution pipe network.

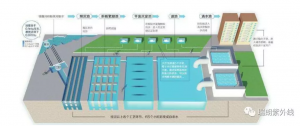

2. UV disinfection

瑞朗紫外线自来水消毒设备

Although chlorine disinfection is the most widely used disinfection method, due to the existence of chlorinated disinfection by-products and the resistance of Giardia and Cryptosporidium to chlorine disinfectants, more and more water plants choose other alternatives. The UV disinfection system has many natural advantages.

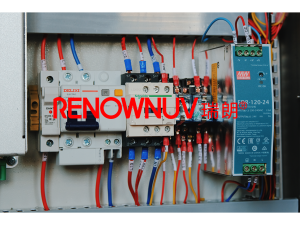

瑞朗紫外线消毒器控制箱

瑞朗紫外线设备

- Unlike chemical treatment, UV does not introduce toxins or residues into the process water, nor does it change the chemical composition, taste, smell or pH of the liquid being disinfected.

- UV treatment can be used in primary disinfection or as a synergistic application of other purification methods, such as carbon filtration systems, reverse osmosis systems, or backwash systems. Since UV disinfection has no residual effect, the best place to install the treatment system is just before the point of use. This ensures that the incoming microbial contaminants are destroyed and the possibility of contamination after treatment is small.

- It is recognized as the lowest cost disinfection method (equipment cost, use cost, maintenance cost, etc.) by the US EPA.

Renownuv Vision: By focusing on the continuous development of products and services to guide customer needs, become a professional company recognized by global users.

Renownuv mission: establish a highly competitive technology company through a unique culture, provide customers with excellent products, and enable them to establish a deep relationship with the company.

This article is Renownuv’s original article, please attach the source for reprinting:www.renownuv.com