The membrane separation performance is evaluated according to the cut-off molecular weight. RO has the best retention performance and can remove most of the ions in water; however, it has high operating pressure and high energy consumption, so it is not suitable as a treatment process in drinking water plants. UF and MF can intercept most of the suspended solids, colloids and bacteria in the water, but the removal rate of organic matter in the water is very low, only below 20%, and cannot remove the precursors of THMs. And UF is a low-pressure driven membrane, and its molecular weight cut-off is relatively high, so it is unfavorable for the removal of lower molecular weight organics in water.

The best method is to combine activated carbon with UF or MF to form an adsorption-solid-liquid separation process for water purification, which can effectively remove low molecular weight organics from the water. NF is a charged membrane with ion selectivity. It has a particularly high removal rate for divalent ions such as calcium and magnesium. It is suitable for raw water with high hardness and organic matter and low turbidity in purified water.

03Photochemical oxidation technology

The photo-oxidation technology of drinking water is a technology that uses visible light or ultraviolet light to carry out complex reactions to deeply treat drinking water. The photo-oxidation technology has strong oxidizing ability, high organic matter removal efficiency, and can effectively decompose pollutants that are preferentially controlled by organic in water.

Photo-activated oxidation technology uses O3, H2O2, O2 and air as oxidants, and combines the oxidation effect of oxidants with photochemical radiation to generate radicals with strong oxidizing power such as -OH. The oxidation effect is better than using UV alone. Or O3 is good.

Photocatalytic oxidation is to add a certain amount of semiconductor catalysts (such as TiO2, WO3, Fe2O3 and CdS, etc.) to water to generate free radicals with strong oxidizing ability under UV radiation to oxidize organics in the water. A large number of studies at home and abroad have shown that the nano-TiO2 photocatalytic oxidation technology has a wide range of applicability for the removal of pollutants in water, for halogenated aliphatic hydrocarbons, nitroaromatics, polycyclic aromatic hydrocarbons, heterocyclic compounds, hydrocarbons, phenols, Surfactants, pesticides, etc. can be effectively degraded and have broad prospects in the advanced treatment of drinking water. The method has strong oxidizing properties, no selectivity for decomposition objects, and can finally completely mineralize organic matter, and has obvious advantages in drinking water treatment.

04Activated carbon adsorption technology

Activated carbon treatment technology is an advanced treatment technology widely used at home and abroad in the 1960s. It is one of the most mature and effective methods to improve conventional treatment processes to remove organic matter in water.

The adsorption process represented by activated carbon has a wide range of raw materials and large adsorption capacity, which can absorb most of the soluble organic substances in water, and has a good removal rate of color, odor, taste, pesticides, chlorides and other organic substances, and has been gradually valued. Priority practical technology for the treatment of organic pollutants. The use of activated carbon in water treatment can effectively remove small molecular organics, but the removal of large molecular organics is limited due to the pore structure. When the organic content in the water is high, the adsorption of activated carbon will inevitably accelerate the saturation and shorten the life cycle. Moreover, the removal ability of polar short-chain oxygen-containing organics and halogenated hydrocarbons is not high, so it is often combined with other methods.

05Activated carbon fiber technology

Activated Carbon Fiber (ACF) is a novel high-efficiency adsorption material that has developed rapidly since the 1960s. It is the third-generation activated carbon product after powdered and granular activated carbon (GAC). It has been widely used in the chemical industry, environmental protection, radiation protection, electronics industry, medical, food hygiene, etc. The pore structure of activated carbon fiber is different from traditional activated carbon, and there are big differences in surface morphology, pore structure and pore size distribution. It can be widely used in chemical separation fields such as organic and inorganic wastewater treatment, air purification, solvent recovery and other fields through physical adsorption, chemical adsorption and physical chemical adsorption.

06Chemical Oxidation Technology

In addition to the common chlorine (including liquid chlorine, hypochlorite chlorine, calcium hypochlorite, etc.) that can be used as drinking water disinfectants, there are also O2, ClO2, RNH2Cl, O3, H2O2, KMnO4, and chlorobromine disinfectants , Sodium dichloroisocyanurate, etc. Wet Catalytic Oxidation Process (WAO), which uses high temperature and high pressure oxygen or air to catalyze and oxidize pollutants into inorganic or small molecular organics, has considerable practical value for high-concentration toxic and harmful wastewater that is difficult to biodegrade, and has been successfully used in the treatment of papermaking Wastewater, petrochemical wastewater, etc. However, the operation conditions of this method are strict, the equipment investment required is high, and the treatment effect of some difficult-to-oxidize substances is not good.

Renownuv Vision: By focusing on the continuous development of products and services to guide customer needs, become a professional company recognized by global users.

Renownuv mission: establish a highly competitive technology company through a unique culture, provide customers with excellent products, and enable them to establish a deep relationship with the company.

This article is Renownuv’s original article, please attach the source for reprinting:www.renownuv.com

Drinking water advanced treatment technology is a treatment method used after conventional treatment processes to remove organic pollutants, heavy metal ions or disinfection by-product precursors that are difficult to remove by conventional treatment processes.

Next, Ruilang will introduce several advanced processing technologies to you. When used alone, these technologies cannot remove all the organic matter on each molecular weight segment, but can only remove organic matter within a certain molecular weight range. Therefore, the process is determined by the size and classification of organic matter, and the combined use of several treatment technologies will be the focus of the application of advanced drinking water treatment technologies in the future.

01 Biological treatment technology

Drinking water biological treatment uses the metabolic activities of the microbial population to effectively remove or reduce the mutagenic precursors, some biodegradable organics, ammonia nitrogen, nitrite, and nitrate that may be generated after chlorination. The biological treatment unit can be located in different positions of the traditional water purification process and play different roles.

As a pretreatment, it can effectively improve the coagulation and sedimentation performance of water and reduce the dosage of coagulant by about 25%; after the water is precipitated, it can extend the service cycle of treatment processes such as filtration or activated carbon adsorption, and reduce subsequent treatment For the source water of eutrophic lakes, it can completely replace the pre-chlorination process, effectively denitrify and dephosphorize, and avoid the halogenated organic matter generated by the pre-chlorination process. Biological denitrification technology is the specific application of biological treatment methods. There are two types of in-situ biological denitrification and reactor denitrification (mostly biofilm type). It has the characteristics of high efficiency and low consumption. It is currently in Europe and America, especially in European countries. Multiple applications have gradually attracted attention in our country.

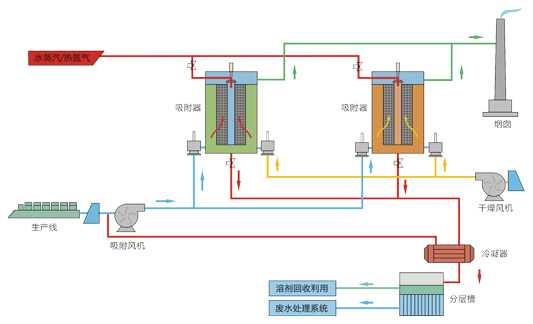

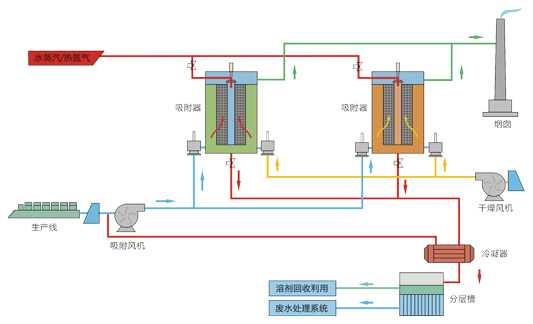

02 Membrane separation technology

Membrane separation technology is a technology that uses the permeability of a specific membrane to separate ions, molecules and impurities in water under a certain driving force. Pressure-driven membrane separation technologies mainly include microfiltration (MF), ultrafiltration (U-trafiltration, UF), nanofiltration (NF) and reverse osmosis (RO).

The membrane separation performance is evaluated according to the cut-off molecular weight. RO has the best retention performance and can remove most of the ions in water; however, it has high operating pressure and high energy consumption, so it is not suitable as a treatment process in drinking water plants. UF and MF can intercept most of the suspended solids, colloids and bacteria in the water, but the removal rate of organic matter in the water is very low, only below 20%, and cannot remove the precursors of THMs. And UF is a low-pressure driven membrane, and its molecular weight cut-off is relatively high, so it is unfavorable for the removal of lower molecular weight organics in water.

The best method is to combine activated carbon with UF or MF to form an adsorption-solid-liquid separation process for water purification, which can effectively remove low molecular weight organics from the water. NF is a charged membrane with ion selectivity. It has a particularly high removal rate for divalent ions such as calcium and magnesium. It is suitable for raw water with high hardness and organic matter and low turbidity in purified water.

03Photochemical oxidation technology

The photo-oxidation technology of drinking water is a technology that uses visible light or ultraviolet light to carry out complex reactions to deeply treat drinking water. The photo-oxidation technology has strong oxidizing ability, high organic matter removal efficiency, and can effectively decompose pollutants that are preferentially controlled by organic in water.

Photo-activated oxidation technology uses O3, H2O2, O2 and air as oxidants, and combines the oxidation effect of oxidants with photochemical radiation to generate radicals with strong oxidizing power such as -OH. The oxidation effect is better than using UV alone. Or O3 is good.

Photocatalytic oxidation is to add a certain amount of semiconductor catalysts (such as TiO2, WO3, Fe2O3 and CdS, etc.) to water to generate free radicals with strong oxidizing ability under UV radiation to oxidize organics in the water. A large number of studies at home and abroad have shown that the nano-TiO2 photocatalytic oxidation technology has a wide range of applicability for the removal of pollutants in water, for halogenated aliphatic hydrocarbons, nitroaromatics, polycyclic aromatic hydrocarbons, heterocyclic compounds, hydrocarbons, phenols, Surfactants, pesticides, etc. can be effectively degraded and have broad prospects in the advanced treatment of drinking water. The method has strong oxidizing properties, no selectivity for decomposition objects, and can finally completely mineralize organic matter, and has obvious advantages in drinking water treatment.

04Activated carbon adsorption technology

Activated carbon treatment technology is an advanced treatment technology widely used at home and abroad in the 1960s. It is one of the most mature and effective methods to improve conventional treatment processes to remove organic matter in water.

The adsorption process represented by activated carbon has a wide range of raw materials and large adsorption capacity, which can absorb most of the soluble organic substances in water, and has a good removal rate of color, odor, taste, pesticides, chlorides and other organic substances, and has been gradually valued. Priority practical technology for the treatment of organic pollutants. The use of activated carbon in water treatment can effectively remove small molecular organics, but the removal of large molecular organics is limited due to the pore structure. When the organic content in the water is high, the adsorption of activated carbon will inevitably accelerate the saturation and shorten the life cycle. Moreover, the removal ability of polar short-chain oxygen-containing organics and halogenated hydrocarbons is not high, so it is often combined with other methods.

05Activated carbon fiber technology

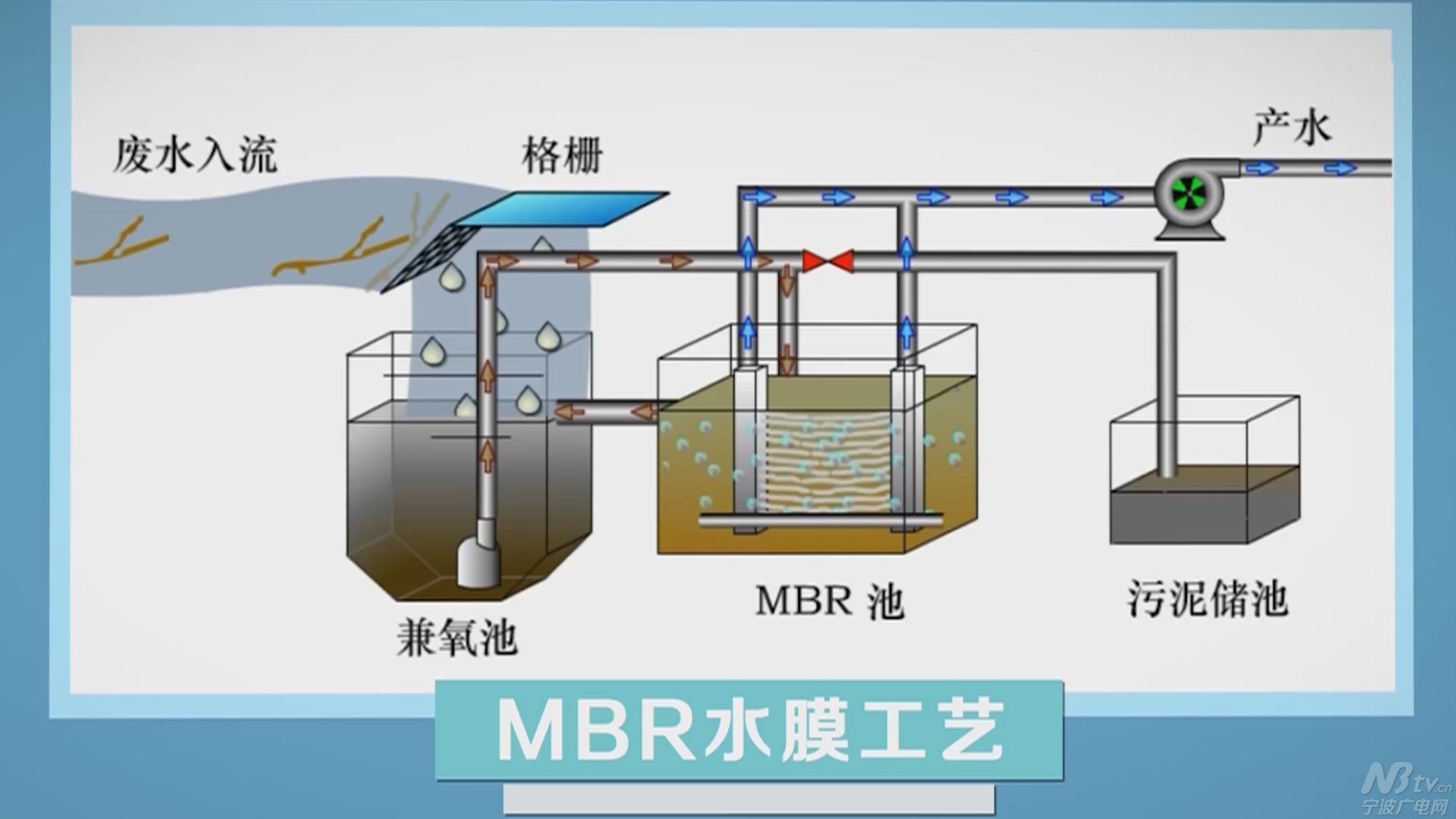

Activated Carbon Fiber (ACF) is a novel high-efficiency adsorption material that has developed rapidly since the 1960s. It is the third-generation activated carbon product after powdered and granular activated carbon (GAC). It has been widely used in the chemical industry, environmental protection, radiation protection, electronics industry, medical, food hygiene, etc. The pore structure of activated carbon fiber is different from traditional activated carbon, and there are big differences in surface morphology, pore structure and pore size distribution. It can be widely used in chemical separation fields such as organic and inorganic wastewater treatment, air purification, solvent recovery and other fields through physical adsorption, chemical adsorption and physical chemical adsorption.

06Chemical Oxidation Technology

In addition to the common chlorine (including liquid chlorine, hypochlorite chlorine, calcium hypochlorite, etc.) that can be used as drinking water disinfectants, there are also O2, ClO2, RNH2Cl, O3, H2O2, KMnO4, and chlorobromine disinfectants , Sodium dichloroisocyanurate, etc. Wet Catalytic Oxidation Process (WAO), which uses high temperature and high pressure oxygen or air to catalyze and oxidize pollutants into inorganic or small molecular organics, has considerable practical value for high-concentration toxic and harmful wastewater that is difficult to biodegrade, and has been successfully used in the treatment of papermaking Wastewater, petrochemical wastewater, etc. However, the operation conditions of this method are strict, the equipment investment required is high, and the treatment effect of some difficult-to-oxidize substances is not good.

Renownuv Vision: By focusing on the continuous development of products and services to guide customer needs, become a professional company recognized by global users.

Renownuv mission: establish a highly competitive technology company through a unique culture, provide customers with excellent products, and enable them to establish a deep relationship with the company.

This article is Renownuv’s original article, please attach the source for reprinting:www.renownuv.com