Ultraviolet rays are well known to the public due to their extensive sterilization and disinfection capabilities. But with the deepening of ultraviolet technology, ultraviolet light has also been widely used in the field of photochemical decomposition. Pure water production process , the UV dechlorination is very mature photochemical applications. Let us understand it together.

Residual chlorine disinfection technology is widely used. About 80% of countries or regions in the world use chlorine to disinfect municipal tap water. The usual method is to pass chlorine or chlorine dioxide into tap water to form a secondary with super oxidizing power. Chloric acid and hypochlorite can kill many kinds of bacteria.

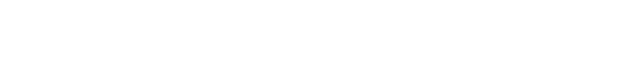

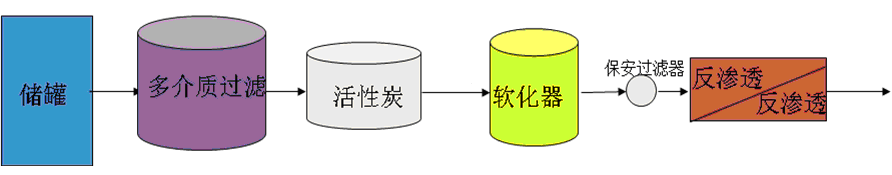

However, the pure aquatic line , since R/O film chloro not tolerated is a must dechlorination step, conventional processes generally use activated carbon filtration or adsorption NaHSO3 reduction methods remove the residual chlorine .

1、Activated carbon to remove residual chlorine

At present, the technology of removing residual chlorine by activated carbon has become the most widely used technology for removing residual chlorine in China.

Activated carbon filtration adsorption method

Activated carbon filtration adsorption method is very effective in removing residual chlorine in water. Its working principle is:

2HOCl + C1 —>CO2 + 2HCl

Where C1 stands for activated carbon. After the activated carbon adsorbs the residual chlorine on its surface, it relies on the carbon base to perform a thorough reaction on the catalytic reduction of residual chlorine substances, thereby reducing and decomposing the oxidizing ClO- ions into non-oxidizing chlorine ions and carbon dioxide.

During the filtration and adsorption process of activated carbon, the total amount of activated carbon will decrease. Therefore, it is necessary to replace the activated carbon regularly to ensure its dechlorination effect. At the same time, after the activated carbon layer adsorbs organic matter, the middle and lower filter material of the activated carbon filter will become a breeding ground for microorganisms. Therefore, good operation management and disinfection measures are required to avoid the risk of microbial growth and contamination.

2、Removal of residual chlorine by sodium bisulfite

Another traditional method for removing residual chlorine is sodium bisulfite reduction.

Sodium bisulfite reduction method

Its working principle is:

2NaHSO3 + 2HOCl—>H2SO4 + 2HCl + Na2SO4。

When chemical dosing is used to treat oxidizing substances such as residual chlorine in the water, an oxidizing substance detection instrument (ORP meter) is often installed to control the dosage of sodium bisulfite in the water to ensure that it enters the next processing unit. The content of oxidized substances in the water has been effectively reduced.

The advantages of this dosing method are: low cost, easy operation,

But its shortcomings are also very clear:

1. The dosing amount is achieved through the meter control of the dosing pump frequency, there may be the risk of meter probe failure and unstable control

2. Since the reduction reaction can only occur through the addition of chemicals, the intervention of a large number of foreign chemicals increases the processing load of the back-end purification system (RO/EDI system), which will affect the service life of the RO membrane in severe cases.

3. Sodium bisulfite solution is very easy to fail in the air. Generally, it takes 3 days to prepare the medicine again, which brings a lot of inconvenience to the operation.

3、UV dechlorination method

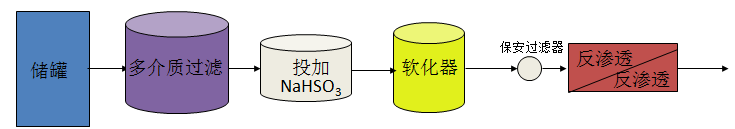

Its working principle is to realize 100% photolysis of residual chlorine through ultraviolet light. The principle of ultraviolet light to decompose residual chlorine is as follows:

2HOCl +2hn —>O2 + 2HCl; 2OCl- +2hn —> O2 + 2Cl-.

Under normal circumstances, the ultraviolet dose used for photolysis of residual chlorine is more than 20 times the standard ultraviolet disinfection dose. Whether the residual chlorine can be successfully removed is related to the ultraviolet radiation dose.

The concentration and pH of the residual chlorine in the raw water will determine the level of UV dose required. The main components of residual chlorine for disinfection are HOCl and OCl-, and their absorption wavelengths of ultraviolet rays are mainly concentrated between 260-320nm.

Compared with the limitations of traditional methods, UV removal of residual chlorine has absolute advantages:

(1) Efficiently remove residual chlorine while completely inactivating microorganisms in the source water to avoid microbial contamination in the RO system;

(2) Ensure microbial safety from the source, and improve the quality of system inlet water;

(3) Online UV intensity monitoring and dose display are allowed, which can accurately predict the dechlorination effect;

(4) It occupies a small space, and the system itself is very clean, without regular cleaning and disinfection;

(5) There is no need to add any chemicals, which can avoid the scaling problem of RO system.

At the same time, the decomposition efficiency of medium-pressure multi-spectral ultraviolet rays on residual chlorine is far better than that of low-pressure monochromatic ultraviolet. The use of medium-pressure multi-spectral ultraviolet rays to remove residual chlorine can effectively reduce the number of UV lamps, thereby reducing the initial investment cost of the system And subsequent maintenance costs.

Due to its many advantages in process applications, UV dechlorination technology is bound to attract more and more professional and technical personnel’s attention and attention; at the same time, the purification water system of the pharmaceutical industry has strict requirements for microbial control, which will also promote UV dechlorination technology With more and more popularization and application, the medium-pressure multi-spectrum ultraviolet technology is bound to become another epoch-making dechlorination product in the purified water preparation industry due to its unique technical advantages.

Renownuv Vision: By focusing on the continuous development of products and services to guide customer needs, become a professional company recognized by global users.

Renownuv mission: establish a highly competitive technology company through a unique culture, provide customers with excellent products, and enable them to establish a deep relationship with the company.

This article is Renownuv’s original article, please attach the source for reprinting:www.renownuv.com