Ultraviolet sterilizer is composed of several ultraviolet disinfection modules with low water resistance, including: stainless steel reactor, ultraviolet lamp tube, quartz sleeve, cleaning structure, distribution system and data acquisition system.

Typical UV sterilizer

Ultraviolet sterilizer USES high intensity ultraviolet C (UVC) illuminant to irradiate water, when the bacterium in the water, virus, algal biology is subjected to the UVC irradiation of certain dose, the DNA of its cell, RNA structure is destroyed, bacterium virus loses the ability of self-replication, achieve the purpose of water disinfection and purification thereby.

(Schematic Diagram of ULTRAVIOLET sterilization)

In the ultraviolet sterilizer, the ultraviolet lamp tube is the important component, its service life and the quality are directly related to the ultraviolet sterilizer disinfection effect and the quality.In the process of using the lamp tube ultraviolet radiation dose attenuation, which will affect the sterilization effect, the need for regular replacement and maintenance.We recommend the use of imported uv lamp, although the price will be slightly higher than domestic brands, but from the use of effect and energy conservation and environmental protection, are better.

UV sterilizer maintenance and maintenance

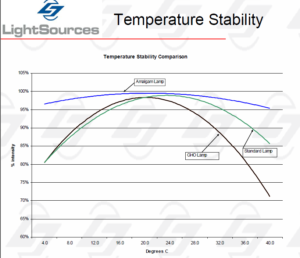

1. Better conditions for the use of uv sterilizer: temperature 20℃ ~ 40℃, humidity 40% ~ 60%

(UV sterilization efficiency varies with temperature)

2. Check regularly to ensure the normal operation of the ULTRAVIOLET lamp.Ultraviolet lamp should be in the state of continuous open, repeated switch will seriously affect the service life of the lamp.

3. Clean the glass tube regularly: According to the water quality, the casing shall be cleaned regularly to remove the dirt on the quartz glass tube, so as not to affect the ultraviolet transmittance and affect the sterilization effect.For large equipment, we recommend using the equipment with automatic cleaning system for easier maintenance.

4. Replacement of lamp tube: according to the use time or strength monitor data.The imported lamp shall be used for 9000 hours continuously, and the ultraviolet lamp shall be replaced after about one year to ensure the sterilization rate.When replacing the lamp, unplug the lamp socket first, take out the lamp, and then carefully insert the new lamp into the sterilizer, install the sealing ring, check whether there is leakage, and then plug in the power.Be careful not to touch the quartz glass of the new lamp tube with your fingers, otherwise it will affect the sterilization effect due to the stain.

5. Prevention of ULTRAVIOLET radiation: ULTRAVIOLET radiation has a powerful lethal effect on bacteria, and also has certain harm to the human body. When starting the disinfection lamp, avoid direct irradiation on the human body, use protective glasses when necessary, and do not directly face the light source with eyes, so as not to burn eyes.

In addition, it should be noted that there is a space for the installation position to draw out the ULTRAVIOLET lamp tube. The electric control box is installed near the device, and the environmental relative humidity is no more than 80℃. There is no corrosive gas, no conductive dust, and no strong vibration and impact.